Expanding on the numerous advantages of purchasing a laser cutting machine from an Indian manufacturer like Prakash Laser, this blog will comprehensively explore the key benefits in greater detail, highlighting financial savings, faster delivery, after-sales support, local market expertise, and the broader impact of supporting domestic manufacturing. We will also delve into the technological and economic landscape of India’s manufacturing sector, discuss the contributions of manufacturers like Prakash Laser, and explore how choosing domestic solutions aligns with the country’s “Make in India” initiative. Let’s break down these benefits further to provide a deeper understanding of why investing in a laser cutting machine from an Indian manufacturer could be one of the best decisions for your business.

1. Financial Savings: A Crucial Factor

When purchasing industrial equipment like a laser cutting machine, the initial cost is just one part of the total expense. For companies looking to import these machines, costs quickly add up with shipping fees, customs duties, and the potential risk of currency fluctuation, which can drastically increase the final price. Opting for an Indian manufacturer significantly reduces these additional costs.

• Cost of Importing vs. Domestic Production: Importing a machine from abroad comes with multiple hidden costs. You may face additional fees related to customs and import taxes, which vary based on the country of origin. Additionally, currency exchange rates can affect your final price, making budgeting more challenging. With domestic production, these financial complexities are eliminated, leading to lower upfront costs and more transparent pricing.

• Competitive Pricing Models: Indian manufacturers like Prakash Laser are well aware of the cost-sensitive nature of the market and are able to provide pricing that is competitive on a global scale. Not only do they offer high-quality machines at competitive rates, but their machines are also customized for the specific needs of Indian industries, ensuring that you get value for money.

• Access to Government Incentives: India’s government has put in place a variety of incentives aimed at promoting local manufacturing, which further reduces costs for domestic buyers. Through initiatives like “Make in India” and the provision of tax benefits for Indian manufacturers, buyers can take advantage of r educed taxes and subsidies. These incentives make investing in Indian-manufactured equipment more attractive than ever.

2. Faster Delivery and Installation of Laser Cutting Machine

Time is of the essence for businesses that rely on precision tools like laser cutting machines. Delays in machine delivery can lead to operational standstills and production slowdowns. One of the greatest advantages of purchasing from an Indian manufacturer is the faster turnaround time compared to importing.

• Local Manufacturing Leads to Quicker Delivery: International shipping timelines are subject to many unpredictable factors, such as port delays, shipping logistics, and customs clearance. By sourcing your laser cutting machine from a domestic company like Prakash Laser Faridabad, you can avoid these hurdles and receive your equipment much faster.

• Minimized Downtime: When you work with Indian manufacturers, delivery and installation processes are not only quicker but also more streamlined. Prakash Laser, for instance, has a robust nationwide service network, ensuring timely delivery and expert installation. A shorter delivery window allows businesses to get their equipment up and running more quickly, which is crucial for meeting production timelines.

3. Superior After-Sales Support and Expertise for Laser Cutting Machine

One of the critical challenges of purchasing industrial machinery from overseas suppliers is ensuring reliable and timely after-sales support. For many businesses, technical issues, machine breakdowns, and maintenance are inevitable. When your machine is from a foreign manufacturer, coordinating support services can be time-consuming and expensive. In contrast, Indian manufacturers like Prakash Laser offer a significant edge when it comes to after-sales service.

• Responsive and Accessible Service Teams: Indian manufacturers have local service teams who are readily available to attend to any issues that arise. Prakash Laser, for example, has an extensive network of service engineers across India, which ensures a quick response to any technical difficulties. This reduces the likelihood of long production delays caused by waiting for parts or service personnel from overseas.

• On-Site Training and Maintenance: Understanding the intricacies of operating a laser cutting machine is vital to ensuring opp0ytimal performance and longevity. Indian manufacturers like Prakash Laser provide comprehensive training programs, equipping operators with the skills needed to manage their machines efficiently. Additionally, these manufacturers offer on-site maintenance services, helping to ensure that your machine operates without interruptions.

• Spare Parts Availability: One of the major issues faced by companies importing machines is the lack of immediate access to spare parts. If a machine part fails, waiting for an international shipment can take days or even weeks. Indian manufacturers, on the other hand, keep a stock of spare parts readily available, minimizing downtime due to mechanical failure.

4. Customization and Flexibility in Laser Cutting Machine Tailored to Your Needs

Every industry has unique requirements when it comes to laser cutting, and a one-size-fits-all approach is rarely optimal. Indian manufacturers like Prakash Laser offer flexibility in designing and customizing machines according to the specific needs of their clients.

• Customized Machine Configurations: Prakash Laser understands that industries have diverse needs in terms of cutting parameters, bed sizes, and automation features. Their team works closely with clients to understand their production goals and customize their machines accordingly. Whether it’s adjusting the power output for cutting thicker materials or modifying bed sizes for larger components, Indian manufacturers offer a high degree of customization.

• Adapting to New Technologies: Indian companies like Prakash Laser are committed to continuous improvement and innovation. They prioritize adopting the latest advancements in laser technology, ensuring that their machines are equipped with cutting-edge features. This focus on innovation means that Indian manufacturers are always looking for ways to improve machine performance and offer new solutions to their customers.

5. Language and Cultural Advantages: Better Communication

Effective communication is crucial in any business relationship, and purchasing industrial machinery is no different. When dealing with foreign suppliers, language barriers can result in miscommunications that may delay processes or result in misunderstandings regarding technical details. By choosing an Indian manufacturer, you avoid these potential pitfalls.

- Seamless Communication: When working with an Indian company, the commonality of language—whether it be Hindi, English, or any other regional language—makes communication smoother and more efficient. Clearer communication results in fewer errors, quicker problem-solving, and greater overall satisfaction during the purchasing process. Prakash Laser’s dedicated customer support team is multilingual, ensuring that all clients, regardless of their location in India, can communicate effectively.

- Understanding of Local Industry Needs: Indian manufacturers have a better understanding of the unique challenges and requirements faced by Indian industries. They are familiar with the local working conditions, market trends, and production demands. Prakash Laser, for instance, has experience working with companies in industries such as aerospace, automotive, and consumer goods, allowing them to tailor solutions specifically to the needs of these sectors.

6. Contributing to the Indian Manufacturing Ecosystem

By choosing to buy from an Indian manufacturer, you’re not just making a business decision—you’re also contributing to the growth of the country’s manufacturing sector. The success of companies like Prakash Laser has a ripple effect, fostering job creation, technological advancements, and overall economic growth.

- Supporting the “Make in India” Initiative: One of the cornerstones of India’s manufacturing policies is the “Make in India” initiative, which encourages companies to manufacture within the country rather than relying on imports. By purchasing from an Indian company, you are supporting this initiative, helping to build a stronger and more self-reliant Indian economy.

- Fostering Innovation and Competitiveness: Indian manufacturers are in a competitive landscape, both domestically and globally. This drives them to continuously improve their products and invest in research and development. Companies like Prakash Laser are committed to pushing the boundaries of what’s possible in laser cutting technology, ensuring that India remains a strong player in the global market.

- Job Creation and Economic Growth: Manufacturing is one of the largest job creators in India. By supporting Indian manufacturers, you are indirectly contributing to job creation in the country, which helps improve the standard of living and boosts overall economic development.

7. Prakash Laser: A Trusted Partner for Your Business

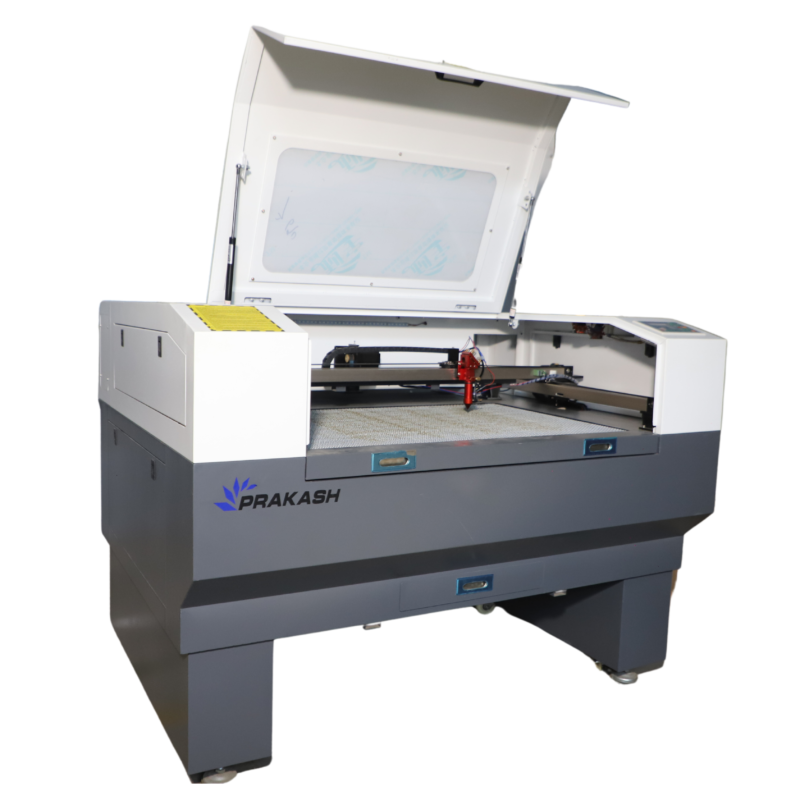

As a leader in the Indian laser cutting machine market, Prakash Laser is well-positioned to meet the diverse needs of industries across the country. With a wide range of machines, from CO2 lasers to fiber lasers, they offer solutions that cater to a variety of materials and cutting requirements. Here’s what sets them apart:

- Wide Range of Products: Prakash Laser provides both CO2 and fiber laser machines, ensuring that their clients can find the right machine for their specific application, whether it’s cutting metal, plastic, or other materials.

- Commitment to Quality: Using high-quality components and stringent quality control processes, Prakash Laser ensures that every machine they produce delivers exceptional performance and durability.

- Focus on Innovation: Prakash Laser is committed to continuous research and development, ensuring that their machines are at the cutting edge of laser technology.

Conclusion

Investing in a laser cutting machine from an Indian manufacturer like Prakash Laser offers numerous benefits. From significant cost savings and faster delivery times to superior after-sales support and machine customization, the advantages of going local are clear. By supporting Indian manufacturers, you’re not only making a smart business decision but also contributing to the growth and development of India’s manufacturing ecosystem. So, whether you’re a small business or a large-scale manufacturer, consider the long-term benefits of partnering with a trusted Indian company like Prakash Laser for your laser cutting needs.

Q1. What is the difference between CO2 and fiber laser cutting machines?

Ans. CO2 lasers are typically used for cutting non-metals like wood, acrylic, and glass, while fiber lasers are more suitable for metals such as steel, aluminum, and copper. For detail information you can contact our laser machine expert visit www.lasercuttingmachines.co.in

Q2. Why should I consider buying from a domestic manufacturer instead of importing?

Ans. Buying from a domestic manufacturer offers benefits such as reduced costs (no shipping or customs fees), faster delivery, local after-sales support, and easier access to spare parts. You also contribute to the local economy and can communicate more effectively with the manufacturer for any customization or support needs.

Q3. Is there training available for operating a laser cutting machine?

Ans. Yes, Prakash Laser provide comprehensive training on how to operate the machine efficiently and safely. This training may include machine setup, software usage, material handling, and maintenance practices, ensuring that your staff is well-equipped to use the machine effectively.

Q4. What industries commonly use laser cutting machines?

Ans. Laser cutting machines are widely used in various industries, including automotive, aerospace, metal fabrication, electronics, construction, medical device manufacturing, jewelry design, and signage. Their precision and versatility make them suitable for both large-scale industrial production and detailed design work.

Q5. How accurate is laser cutting compared to other cutting methods?

Ans. Laser cutting is highly accurate, with precision levels up to 0.1mm or less, depending on the machine and material. It provides cleaner cuts with minimal material distortion, making it far more precise than traditional mechanical cutting methods such as sawing or punching.