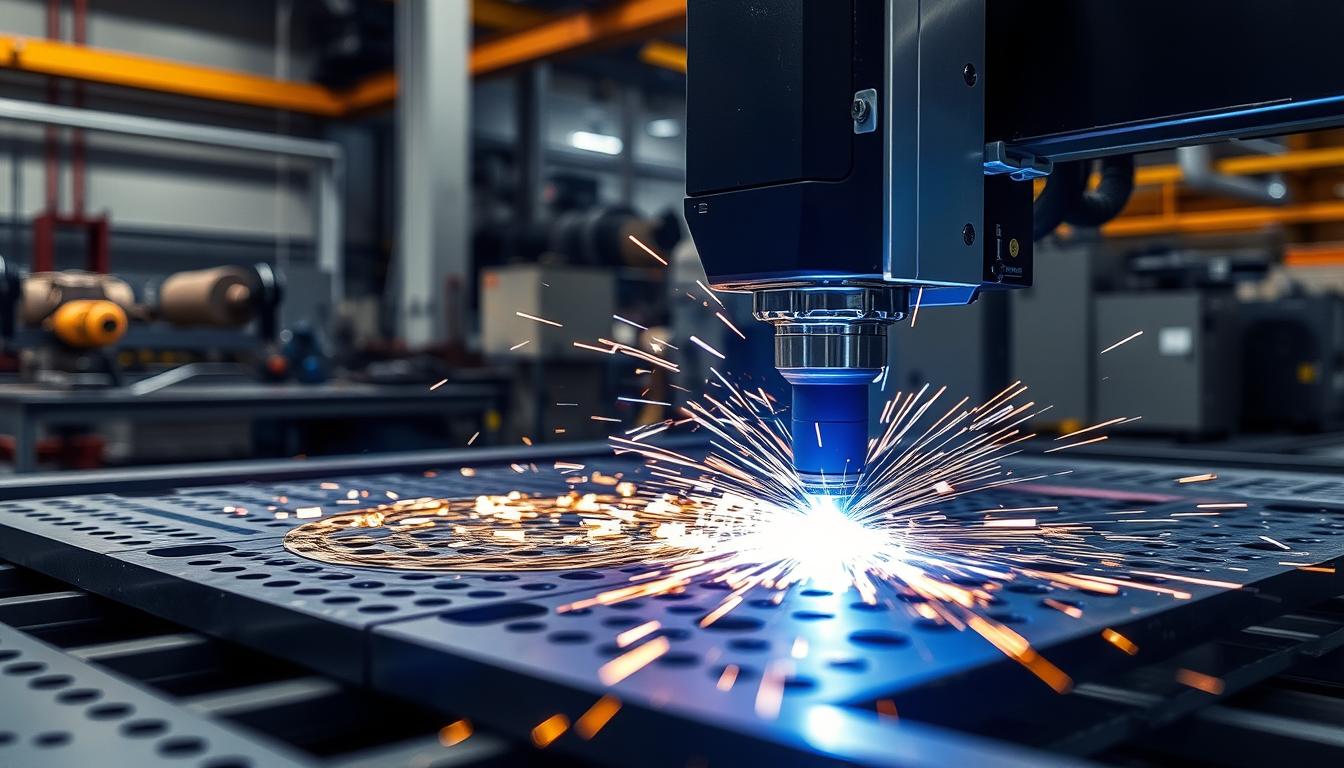

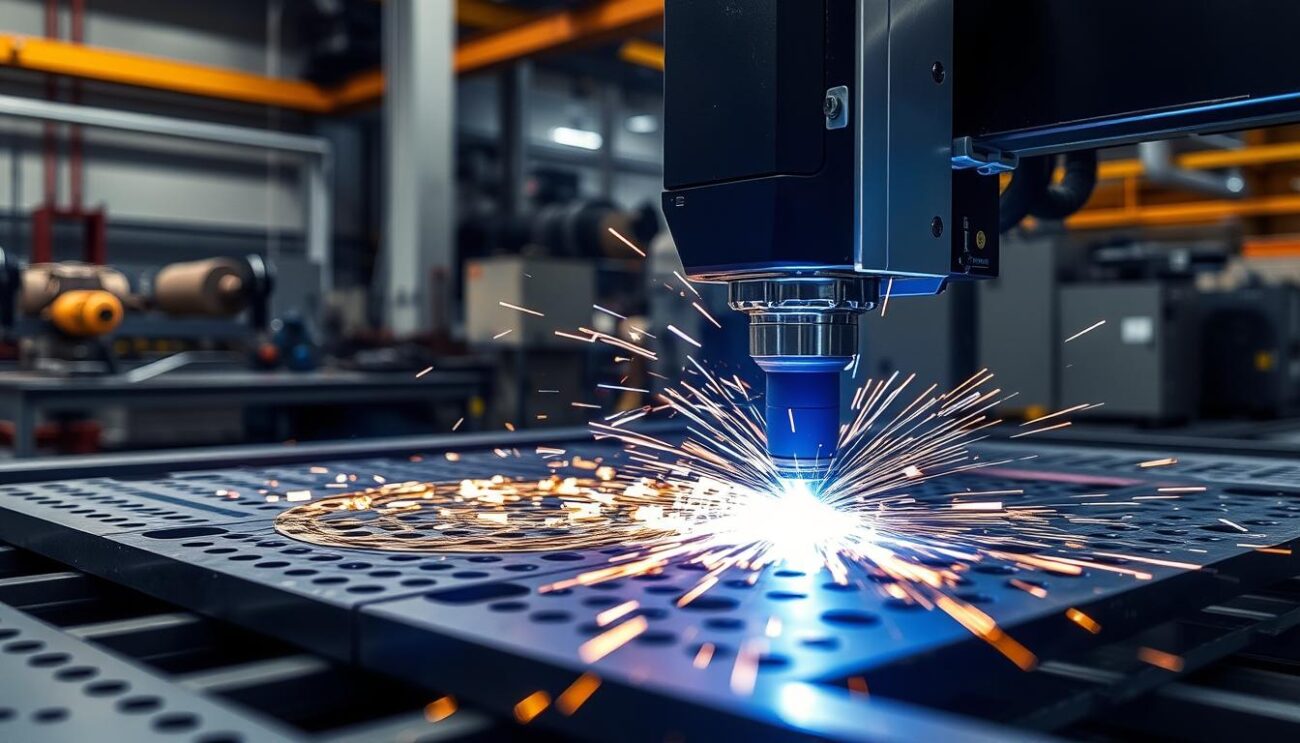

Fiber laser cutting machine are versatile tools used in many industries, including automotive, aerospace, medical device manufacturing, and tools & machinery production. These machines excel at cutting and shaping various metals with exceptional precision and cost-effectiveness. They are a preferred choice for companies seeking a reliable and efficient metal laser cutting solution.”

Fiber laser cutting machines have changed the game in manufacturing. They cut and shape materials with amazing precision. If you’re looking for a metal cutting machine, finding the best metal laser cutting machine is key.

The main parts of these machines are the laser source, beam delivery system, and cutting head. Together, they make high-quality cuts with little waste. Fiber laser cutting machines beat old methods with faster speeds and better accuracy.

Applications of Fiber Laser Cutting Machine

1. Automotive Manufacturing:

The automotive industry uses fiber laser cutting machine technology a lot. It’s great for making complex parts with high precision. These machines cut and shape parts like car bodies, engine parts, and exhaust systems. Using metal laser cutting machine tech helps cut down on waste and makes production faster.

Some main uses of fiber laser cutting machine tech in cars include:

- Cutting and shaping car bodies and chassis parts

- Precise cutting of engine parts, like cylinder blocks and heads

- Making exhaust systems and other car parts

Adding metal laser cutting machine tech to car making has changed the game. It lets makers create complex shapes and designs with great precision. As car making keeps getting better, fiber laser cutting machine tech will be key in shaping the future.

| Application | Benefits |

|---|---|

| Cutting and shaping of car bodies | High precision and accuracy, reduced material waste |

| Precision cutting of engine parts | Improved production efficiency, reduced production time |

| Manufacturing of exhaust systems | Increased accuracy, reduced material waste |

3. Metal Fabrication and Sheet Metal Processing by Fiber Laser Cutting Machine:

Metal fabrication and sheet metal processing are key areas where fiber laser cutting machine tech stands out. These machines offer unmatched precision and accuracy. They are perfect for cutting and shaping metals like steel, aluminum, and copper.

In metal fabrication, a metal laser cutting machine makes creating complex shapes and designs easy. This approach cuts down on material waste and boosts production speed. Key advantages of using a fiber laser cutting machine include:

- High precision and accuracy

- Reduced material waste

- Improved production efficiency

- Ability to cut complex shapes and designs

Using a fiber laser cutting machine elevates metal fabrication and sheet metal processing. Its ability to cut through various metals with precision is crucial for these applications.

3. Construction and Architectural Metal Work:

The fiber laser cutting machine is now a key tool in construction and metal work. It cuts and shapes metals like steel, aluminum, and copper with great precision. This makes it very useful for these tasks.

The metal laser cutting machine is vital for making complex shapes and designs. These are crucial for architectural metal work. Using these machines helps reduce waste and boosts efficiency, making them perfect for construction and metal work.

Here are some main uses of fiber laser cutting machine in construction and metal work:

- Cutting and shaping metal sheets for building facades

- Producing complex metal components for architectural features

- Creating custom metal designs for interior and exterior decoration

The metal laser cutting machine has changed the construction and metal work industry. It allows for making detailed and complex metal designs with high precision.

4. Electronics and Consumer Goods Manufacturing by Fiber Laser Cutting Machine:

Fiber laser cutting machines are now key in making electronics and consumer goods. They cut and shape parts with great precision. This includes PCBs, cases for consumer electronics, and small parts. The best metal laser cutting machine cuts down on waste and boosts efficiency, making it vital for makers.

In making consumer electronics, a metal cutting machine shapes metal parts like cases and frames. These machines can make complex shapes and designs. This is crucial for modern electronics. Some main uses of fiber laser cutting machines include:

- PCB manufacturing

- Consumer electronics cases

- Small precision components

Fiber laser cutting machines have changed how electronics and consumer goods are made. They make it easy to create complex and precise parts. With a best metal laser cutting machine or a metal cutting machine, makers can work more efficiently and waste less material. This makes them more competitive in the market.

5. Medical Device Manufacturing Capabilities:

Fiber laser cutting machines have changed the medical device industry. They offer high precision and accuracy. This is key for making complex shapes and designs needed in medical devices. A metal cutting machine is vital for creating detailed parts easily.

When searching for a best fiber laser cutting machine manufacturer near me, think about the medical device industry’s needs. The maker should offer machines that are precise, accurate, and safe. Fiber laser cutting machines are used in many ways in medical device making, such as:

- Surgical instrument production: They help make complex shapes for tools like scissors and scalpels.

- Implant manufacturing: These machines create implants, like hip and knee replacements, with great precision.

- Medical equipment components: They make parts for medical gear, like hospital beds and wheelchairs.

Using fiber laser cutting machines in medical device making has many benefits. It reduces waste and boosts efficiency. As more medical devices are needed, these machines will play a bigger role. This will lead to more innovation and progress in the field.

6. Aerospace Industry:

In the aerospace industry, fiber laser cutting machines play a crucial role in manufacturing various aircraft components. Here’s a more detailed look:

- Engine Components:

- Turbine Blades: These components require intricate shapes and precise cuts to ensure optimal airflow and performance.Fiber lasers can accurately cut the complex geometries of turbine blades from high-strength materials like titanium and nickel alloys.

- Engine Housings: Fiber lasers are used to cut and shape the intricate contours of engine housings, ensuring precise fit and optimal airflow.

- Fuselage Panels:

- Skin Panels: These large, thin panels require precise cuts to maintain the structural integrity of the aircraft. Fiber lasers can cut these panels quickly and accurately, minimizing waste and ensuring a smooth, consistent surface.

- Reinforcements: Fiber lasers are used to cut and shape structural reinforcements within the fuselage, enhancing the aircraft’s strength and rigidity.

- Landing Gear:

- Components: Fiber lasers are used to cut and shape various landing gear components, including struts, wheels, and brakes, from high-strength materials like steel and aluminum alloys.

7. Fitness Industry

Fiber laser cutting machines are extensively used in the fitness equipment manufacturing industry to cut and shape various metal components. Here’s how:

- Frames and Structures:

- Cutting Frames: Fiber lasers precisely cut the intricate shapes required for frames of various fitness equipment, such as treadmills, elliptical machines, and weightlifting benches. These frames often involve complex geometries and require high-precision cuts for optimal strength and stability.

- Structural Components: Fiber lasers cut and shape various structural components like support beams, crossbars, and brackets, ensuring precise dimensions and accurate fit.

- Exercise Equipment Components:

- Weight Stacks: Fiber lasers can cut and shape the individual plates for weight stacks with high precision, ensuring consistent weight and smooth operation.

- Handles and Grips: Fiber lasers can cut and shape handles and grips for various equipment, such as dumbbells, barbells, and exercise machines, with intricate designs and ergonomic contours.

- Exercise Bike Components: Fiber lasers cut and shape components like frames, cranks, and pedals for exercise bikes, ensuring smooth and efficient operation.

Conclusion: The Future of Fiber Laser Cutting in Manufacturing

The manufacturing world is changing rapidly, and fiber laser cutting machines are at the forefront of this transformation. These machines have revolutionized how we cut and shape metals. We’re eagerly anticipating further advancements in fiber laser cutting technology that will unlock new possibilities for manufacturers across diverse sectors.

Fiber laser cutting machines are indispensable in industries such as automotive, aerospace, electronics, and medical device manufacturing. Renowned for their speed, accuracy, and efficiency, these machines are poised to handle even more complex tasks as technology continues to evolve. Companies that embrace this technology will gain a significant competitive edge in the global market.

The environmental sustainability of fiber laser cutting is another major advantage. These machines consume less energy and generate minimal waste, aligning perfectly with the growing demand for eco-friendly manufacturing practices. As businesses strive for greater sustainability, the appeal of fiber laser cutting machines will continue to soar, shaping the future of manufacturing.

Frequently Asked Questions (FAQ’s)

Q1. How does fiber laser cutting technology work?

Ans1. Fiber laser cutting utilizes a high-powered laser beam generated by a fiber optic cable to cut through materials. The focused laser beam creates intense heat, vaporizing the material and enabling precise cutting.

Q2. What factors should be considered when choosing a fiber laser cutting machine?

Ans2. When selecting a fiber laser cutting machine, several factors should be carefully considered. These include the machine’s cutting capacity (maximum material thickness), laser power (determining cutting speed and material compatibility), cutting head type (influencing cutting speed, accuracy, and complex shape cutting capabilities), automation capabilities (impacting production efficiency and labor costs), maintenance requirements (ease of maintenance and spare part availability), and budget constraints.

Q3. What are the key factors to consider when comparing laser cutting machine models from different manufacturers?

Ans3. A. Laser Power: Determines the cutting speed and the types of materials that can be cut. B. Cutting Head Technology: Influences cutting speed, accuracy, and the ability to cut complex shapes. C. Control System: The sophistication of the control system impacts ease of use, programming capabilities, and overall machine performance. D. Table Size: Determines the maximum size of the material that can be processed. E. Maintenance Requirements: Consider the ease of maintenance and the availability of spare parts.

Q4. Who are some of the leading laser machine manufacturers in India?

Ans4. Prakash Laser is a well-regarded manufacturer of laser cutting machines in India. They are known for their high-quality fiber laser cutting machines, offering features like high precision, speed, and reliability. Prakash Laser caters to various industries with diverse product offerings. You can find more information on their website: https://www.lasercuttingmachines.co.in/