Deep engraving laser marking machines are used where there is requirement of creating a depth on a workpiece by removing the material surface finely in layers. These machine if used for surface marking can give a larger marking area and also speed up the production process. A small change in speed and power can easily incorporate the marking and deep engraving technology. It is widely used in industries like metal button dies, coin mint dies mold inserts etc.

Best price in INDIA guaranteed!

- Optical fibre laser- Fibre optic cable is used as a source to deliver the Laser beam to do marking.

- Optical Isolator- An optical isolator has been installed on the laser Marking head to prevent the back reflection of laser light on the Laser’s most sensitive optical component.

- Precise scanning system- High speed scanning system has been used in the system to get the speedy and precise results in marking.

- High service life of upto 10 years of the laser source making it more reliable and energy saving

- Over 100,000 hours of reliable, maintenance-free performance

- No consumables required which helps in reducing the operating cost.

- Compact and modular structure to make the operation safe and sound.

- The laser head is sealed so as to prevent the optical chamber from Contamination.

- Visible red diode for aiming and dry run operations.

- Built-in air cooling system.

- Professional Laser marking software with a user friendly interface and the controls that allows the connection to multiple laser systems with one computer.

- Operator Control Panel- The front panel control module includes the system key switch, laser off push button, manual safety shutter control, function indicators.

| Model | ML-MF W201 |

ML-MF W301 |

|---|---|---|

| Laser Type | Fiber |

|

| Laser Power | 20W |

30W |

| Laser Wavelength | 1064mm |

|

| Repeating Freq. | 1-100Khz |

|

| Beam Quality | <2 |

|

| Marking range | 100x100mm |

|

| Marking Depth | 0.1-2mm(Depending material and marking time) |

|

| Marking Speed | <7000mm/s |

|

| Min. Line Width | 0.01mm |

|

| Power Cons. | 800 W |

|

- Index Tables- Normally we offer two station indexing tables. But we can also offer 4, 6, 8, 12 options. Automatic unloading can be discussed too.

- Rotary attachment- This attachment provides a good solution to mark and engrave on cylindrical items like tubes etc.

- Protection Glasses- We can provide high quality optical glasses for protection from laser light.

- Pad Printing Machines- Depending upon the requirement of each application Pad printing machines can also be used to print before or after the laser. To get the information about pad printing machines click here.

- X – Y Tables- We can give x-y tables for precise control of registration.

- Mark on Fly- A special hardware for flying control system can be added to enhance performance and ease the operation.

- Fixtures- High quality fixtures can be provided as per component

- Marking area- As per the customer requirement the size of the marking area can be increased to 200×200 or 300×300 or even bigger.

| Materials | Yes |

|---|---|

| Steel | √ |

| Gold | √ |

| Brass | √ |

| Paper | √ |

| Copper | √ |

| Ceramic | √ |

| Plastics | √ |

| Titanium | √ |

| Magnesium | √ |

| Aluminum | √ |

| Zinc | √ |

ML-MF W201

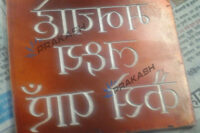

Giving the power of 20w, ML-MF W201 is a robust model designed to work in harsh industrial environment . This model is widely used in stamping tools, punches, buttons industries etc..

ML-MF W301

With a power of 30w, ML_MF W301 is Ideal for much larger productions (depending upon the size and parameters of marking). Giving the speedy and highly précised results , this machine is widely used in industries like dies, button, punches, stamping tools etc.

What is the laser source in deep engraving laser marking machines?

A High Quality Fiber optic cable is used as a laser source in deep Engraving laser marking machines.

How are these machines more beneficial than conventional engraving machines?

Yes, deep Engraving laser machines are much more useful than conventional engraving machines due to:

- Speed: The jobs through laser technology are done 4 times faster as compared to the conventional ones.

- Less consumables: Deep engraving machines use fiber as a laser source which require no consumables.

- Less power: It requires 5 times less power than conventional machine to give a fine output reducing the running cost of machine.

- High precision: Laser machines can do the engraving finely to a much greater extent which is not possible with conventional machines.

Which operating system is supported by software?

Win98/Win2000/WinXP/Win 7

With what file formats is software compatible with?

PLT/ DXF/ BMP/ JPG/ AI

What cooling system is used in the machine?

It has built-in wind cooling system.

What is the repeatablity accuracy of the machine?

±0.002 mm

Can these machines do engraving on metals too?

Yes, Deep Engraving laser Marking machines can mark both on metals and non-metals like Stainless steel, clock, watches

What warranty do I get on purchase of fiber laser marking machine?

One year full warranty and a quick on-demand service is provided with laser marking machines.