Laser marking is a process used to create different characters, numbers, logos and other graphics. This does not involve usage of a tool etching the surface and neither does it uses any ink or other material on the surface. Instead of this laser light is used on a material. This use of laser technology, in turn, helps to produce a contrasting or a deep mark based on the use of particular settings.

Laser marking is a process used to create different characters, numbers, logos and other graphics. This does not involve usage of a tool etching the surface and neither does it uses any ink or other material on the surface. Instead of this laser light is used on a material. This use of laser technology, in turn, helps to produce a contrasting or a deep mark based on the use of particular settings.

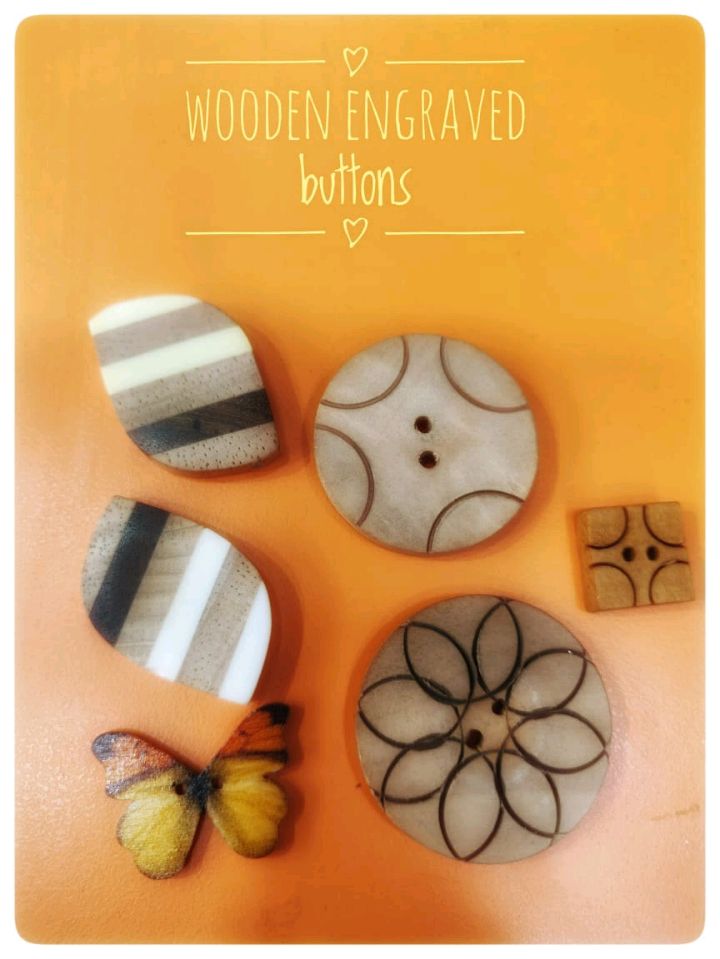

There is a number of buttons laser marking machines available in the market. These machines are capable of handling different amounts of work ranging from small desktop machines to huge integrated systems. While these small machines can handle small batches of printing the others can be used for huge production purposes. The laser marking system is prominent and better than printers as it makes it possible to mark attractive symbols and produce permanent results.

Why laser for marking on buttons

- Laser marking on buttons is much better than any other other forms of printing or marking used in buttons.

- Even the complex artwork are possible to mark/engrave with laser.

- Marking can be done fast within minutes.

- Automating the whole procedure of laser marking is easily possible or can even be integrated in the production line.

- More accuracy.

- Hassle free clean process.

Precision cut and beautiful marking

The use of laser technology makes the engravement of various symbols with precision and perfect marking. The designs formed are beautiful and marked with complete accuracy.

Fiber Laser marking plastic buttons by Prakash laser

Stable output power of the laser source

The use of laser technology improves production power. These are highly developed machines that can make the production process much easier and faster. This continuous detection of power is helpful as it can produce continuous uninterrupted supply and production. This continuous monitoring of power is of help to both the manufacturer and the user.

Meet the demands of mass production

The laser marking machines from Prakash are all operated with the help of computer making it a click and go process. Also, an option of automation and use of fixtures with the existing production line makes easier to meet the demand for mass productions.

Powerful and easy operation

It is simple and easy to operate with perfect results in the shortest time. A laser marking would be easy to be read and completely vibrant. This is, hence, regarded as a superior form of marking compare to that of other marking schemes.

Easy maintenance and convenient dust removing

The use of laser marking can help provide a permanent mark in a while. The speed of these machines is quite fast. It can easily mark different buttons in the least time possible. The process of laser marking is flexible as it would make the process of printing in buttons much easier, irrespective of the kind of material being used in the process. There would be no harm involved in the process of unclogging a printer as the laser marking system is not such complex and neither requires any regular or time to time maintenance.

Low cost

The cost savings are huge as high number manufacturers can greatly reduce the costs of operation with laser marking. In fact, the cost of consumable for labels shall exceed a lot more than the opening cost of the laser.

Creates markings on a wide range of button types

Cloth buttons – Laser marking can be used to make any kind of engraving in buttons of cloth.

Glass buttons – These glass buttons are quite sensitive and might get broken easily. However, the use of laser machines proves the proper use of this technique.

Leather buttons – Leather buttons are another kind yet laser marking is the same process to work here as well.

Metal buttons – The perfect etching can be done by the use of laser technology that can help in the entire engraving process.

Polyester buttons – Another common type of button, the polyester button makes the process of engraving better with its texture and the outcome is completely mind-blowing.

Wood buttons – Whether there is a need to carve any letter, graphic or any artwork, this particular process of laser marking can do wonders.

Conclusion

Laser marking on buttons have become quite common these days and printers are now widely being replaced with the use of laser engraving. Not only because of the ease in production and the mass production rate that is possible but also because of so many benefits as we discussed this process has become a core business technique.