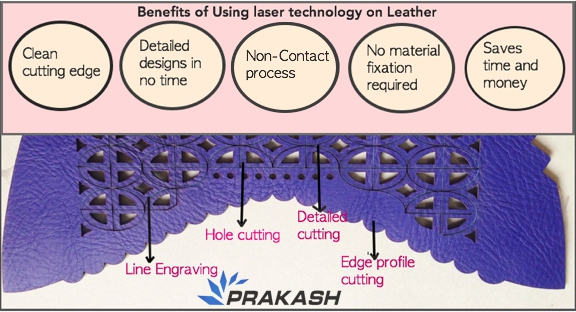

Benefits of Using Laser Technology for Leather Based Products

1. Most manufacturers look for clean edged cuts that do not allow any fraying of leather. Our non-contact laser beam processes do the trick well.

2. You can save on cost, time and money by using our leather laser cutter. We help you cut down on manpower and labor costs manifold. Just one person, with little practice, is capable of handling 4-5 machines at any given point of time.

3. Unlike traditional methods, where leather cannot be engraved and cut at the same time, our machines allow you to do just that – thus bringing in more savings on your costs and time.

4. With these machines, you need not worry about discoloration taking place during the process of cutting and engraving. Our laser leather cutting machines alleviate your concerns by necessitating the use of a masking tape before the procedure.

5. Once a laser cutter has been customized and programmed for a process, it produces high-quality work pieces consistently.

6. Our laser cutting machines feature a specialized exhaust system that controls the emission of harmful gases during the processes of cutting, engraving and/ or marking.

There are many industries that use leather for manufacturing their products. Being the versatile material that it is, leather is capable of retaining its shape and design in all kinds of cutouts. Whether you desire to make large cutouts or small ones, our leather laser cutting and engraving machines will help you get the right shape, pattern and cut in the least possible time.

We take immense pride in the laser technology employed by our leather cutting and engraving machines. Our laser cutting experts use the simplest of processes to craft the most beautiful leather products for all industry verticals. By using our leather cutting technology and engraving methods, you can meet the leather specific requirements of your clients without any concern. Be it for your tablet covers, address card holders, footwear, laptop bags, fancy hold-alls, or anything else – laser cut leather is what you should seek right away.

The precise and accurate processes used in our laser technology applications lead to no distortion or damage of any original material. Our laser leather cutting processes can be tailor made to help leather manufacturers craft the best designs and patterns. We strive to cater to all client requirements – be it big or small!

Benefits of Using Laser Technology on Leather (Infographic)

Leather cutting machines with laser technology: Industrial Applications

1. Wallets, belts, bracelets and other fashion accessories

2. Briefcases, bags, wallets, etc.

3. Footwear

4. Car seat covers

6. Clothing

7. Furniture

8. Gifts and novelties, etc.

Our best laser leather cutting machine models

At Prakash, all our 5 models (P-6040, P-960, P-1390 , P- 1610, P-1325) rank high on the list of the best laser cutters for diverse industrial requirements. Of special mention are P-6040 and P- 960 that are getting raving reviews in the leather industry as the most acceptable models. They feature a single head and are equipped with all the basic functionalities of laser cutting and engraving machines. Our double head (P-960T) model works with twofold speed to enhance the productivity of industries requiring high production capacities. Being one of the leading laser cutting machine supplier and manufacturer we ensure you to give the best leather laser cutting machine price in Industry.

Work on all types of leather

These laser leather cutting and engraving machines are used for processing all kinds of leather – be it synthetic leather, natural leather, napped leather or suede leather, cow leather etc

Watch Leather Laser Cutting Machine in Action

Get Quote Now