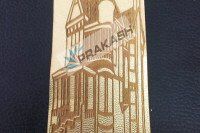

Prakash presents 5 models, namely P-6040, P-960, P-1390, P-1610 and P-1325, of single head cutting machines driven by laser technology. These machines are made of the best quality products and require low maintenance and handling costs. They can be used in diverse work areas for giving the most satisfactory results at all times. As a laser machine manufacturer we understand the basic needs of the machine to run free flow for a long time without any hassle.

best price in INDIA guaranteed

Visible red dot pointer

Red light positioning device indicates the location of laser …

Air assist

With air assist, you can remove the combustible heat …

LCD panel

Crystal display for the friendly interface and make …

Top quality optics

Imported silicon reflectors with a wavelength …

Motion control system

The laser controllers, RD 4.23 allow the system to work …

High quality and long life laser tube.

Imported bearings

Imported japanese bearings and guide rails for …

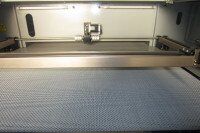

Honeycomb worktable

Honeycomb design work table to give better vacuum …

Water protection

This feature protects the laser tube when the water …

Pass through door design

This design feature helps to cut the long …

Closed loop chiller (100 W and greater)

Click here for technical specifications …

Smart carver controller

This high-tech controller is based on 32 bit …

32M (or higher) mass memory unit

This feature simultaneously saves many …

USB data interface

Power Supply 80 watts

Laser software

Uses is a professional software that controls the system …

Laser tool kit

| Description | P-6040 | P-960 | P-1080 | P-1390 | P-1610 |

|---|---|---|---|---|---|

| Working Area | 600x400 | 900x600 | 1000x800 | 900x1300 | 1600x1000 |

| Laser Power | 30-150W | ||||

| Cutting Speed | 60,000mm/min | ||||

| Power Supply | 220V/50Hz | ||||

| Graphic format supported | DST,PLT,BMP,Autocad | ||||

| Software Supported | Coreldraw,Photoshop,Autocad | ||||

| Driving Motor | Stepper Motor | ||||

| Operating temperature | 0-45°C | ||||

| Operating humidity | 5-95% | ||||

| Equipment Size | 1360x800x1080mm | 1460x800x1080mm | 1560x1250x1080mm | 2080x1300x1300mm | 2080x1300x1600mm |

| Weight | 250 Kg | 280 Kg | 320 Kg | 360 Kg | 420 Kg |

Motorized Table

Controls the table up/down.

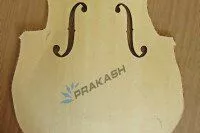

Rotary device

Helps in the fine engraving of cylindrical items like glass, mug etc.

| Materials | Engrave | Cut |

|---|---|---|

| Leather | √ |

√ |

| Cloth | √ |

√ |

| Wool | √ |

√ |

| Plexiglass | √ |

√ |

| Rubber | √ |

√ |

| PVC plate | √ |

√ |

| Acrylic | √ |

√ |

| Aluminium | √ |

√ |

| Wood | √ |

√ |

| Brass | √ |

√ |

| Foam | √ |

√ |

| Paper | √ |

√ |

| Carpet | √ |

√ |

| Plastic | √ |

√ |

| Painted Metals | √ |

|

| Tile | √ |

|

| Glass |

√

|

|

| Ceramics | √ |

|

| Marble | √ |

|

| Granite | √ |

|

| Limestone | √ |

|

| Cork | √ |

Applicable Industries

- Garment Industry

- Packaging

- Electronics

- Toy Industry

- Carpet Industry

- Invitation Cards

- Model Making Industry

- Autoparts

- Barcode Industry

P-6040

It is the basic model of this series and is most accepted in the industries due to its low cost ,high quality and versatility in application. With a work area of 600 X 400 mm, it has high tech smart carve controller whichis based on closed loop motion control system to give very precise, stable and improved outputs.

P-960

with a work area of 900 X 600 mm, CMA 960 remains in demand due to its comfortable size and high precision. You can do both cutting and engraving on variety of materials like wood, leather, fabric ..etc.

P-1390

With a extra-large work area of 900 X 1300mm,CMA 1390 is very good option for cutting acrylic sheet and many other large sized materials at high speed. The special pass through door design helps in handling the long material saving time and labour.This model also remains in high demand in signage industry.

P-1610

with an over-sized work area of 1600 X 1000mm, you can opt for automatic feeding system with multiple heads saving a lot of time and labour.this model gives the substantial space for cutting and engraving large pieces with high precision, speed and stability. Due to this it is quite popular among fabric industries.

What operating system do I need to run prakash laser machines?

The machine runs on window 2000/ XP/ vista/ wins 7 but not on mac OS.

What softwares do I need to design my jobs?

You can use any software among autocad, corel draw and photoshop.

What files is the software compatible with?

JPG, PNG, BMP, PLT, DST, DXF, CDR, AI, DSB, GIF, MNG, TIF, TGA,PCX, JP2, JPC, PGX, RAS, PNM, SKA, RAW

How many computers do I need to handle more than 1 laser machine?

A single computer can control willfully many engraving machines, saving the great cost for the user.

Can I cut and engrave with the same machine?

Yes, you can do both cutting and engraving on non-metals with the same machine.

Do I get any warranty with laser cutting machine?

Yes, you get one year full warranty with the machine.

What is the accuracy of laser systems?

0.1mm

How long does it take to learn to use the machine?

If you know how to use graphic design software, you can be up and running the laser system in minutes. You also do not need any special technician to run and maintain the machines.Prakash laser machines are simple to operate and easy to understand with a little training from our staff.

It will take a bit of trial and error to learn what speed and power settings to use with different materials, but we include a comprehensive guide with your system that has recommended speed and power settings for various materials with which you will be working.

What materials are unsafe to engrave or cut with laser systems?

Hydrogen Chloride and Vinyl Chloride (mostly found in PVC and other man made materials) are hazardous to the life of your laser system. Engraving and cutting these materials can cause irreversible damage to your machine, so determining the components of your cutting and engraving materials is extremely important.